Designing CMP Detention Systems - Design Red Flags

Common Design Mistakes in CMP Detention Systems and How to Avoid Them

Red flags are design elements that are commonly or easily overlooked and may need extra attention when designing. Considering the red flags upfront will expedite the design and fabrication process, and eliminate delays, installation, and performance issues.

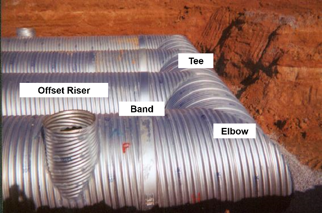

Overlapping welds - Risers cannot be located in the middle of an elbow, as this would result in overlapping welds which weaken the structure. Risers need to be offset, are best placed on the barrel and not the header. This picture illustrates the proper placement of a riser.

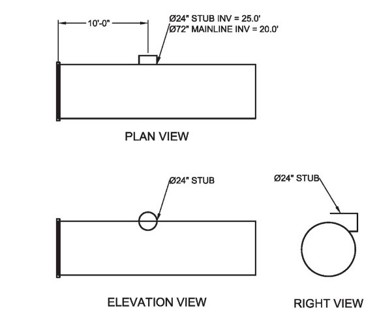

Stub elevations - Stub elevations may look acceptable in plan view, but you need to consider elevation and right views as well. This may seem obvious, but it is very easy to overlook when you are looking at a busy set of plans.

Notice how the crown of the stub has an incorrect higher elevation as compared to the crown of the pipe in the detail.

3. Pipe spacing - Proper pipe spacing and backfill are crucial in the performance CMP detention systems. Spacing is important as there needs to be room for the contractor installing the system to get between the pipes and work the backfill material for proper compaction. The industry standard for spacing is as follows:

· <24” diameter: use 12” spacing

· 24”diameter to 72” diameter: use ½ the diameter of the pipe for spacing

· >72” diameter: use 36” spacing

4. Pipe installed under slopes - You should avoid installing systems under a steep cross slope or next to a slope. For example, installing a system where you have 20’ of cover over one side, and 2’ of cover over the other. This may result in a potential for failure due to a large difference in loads from one side to the other. This is true for any detention material that relies on stone storage, not just CMP.

5. Systems designs at or near a building/structure - CMP detention systems cannot support loading from buildings and other structures. Risks and designs must be analyzed on a project specific basis.

6. Non H20 & H25 loading requirements - This may include firetruck or garbage truck loading. Adjustments to the gauge of the pipe or the minimum cover required may be needed to accommodate larger loads.

7. High groundwater and buoyancy - Whenever the watertable level is above the invert of the pipe, the potential for flotation exists and should be accounted for in your design.

8. Maintain minimum cover requirements – Maintaining the minimum cover requirements are required to ensure the integrity on the system. The values below represent the minimum cover requirements. Cover is measured from the crown of the pipe to the bottom of pavement for flexible pavement or the top of grade for rigid pavement.

· 12” to bottom of flexible pavement for CMP diameters 96” and smaller

· 18” to the bottom of flexible pavement for CMP diameters ranging from 102” through 144”

If you encounter these or other design challenges, remember that Contech’s team of stormwater design engineers have designed thousands of CMP detention systems. There is almost no design challenge they haven’t encountered before, and they are here to help you at every stage or your project.