Create Your Design Using the Contech Design Center

|

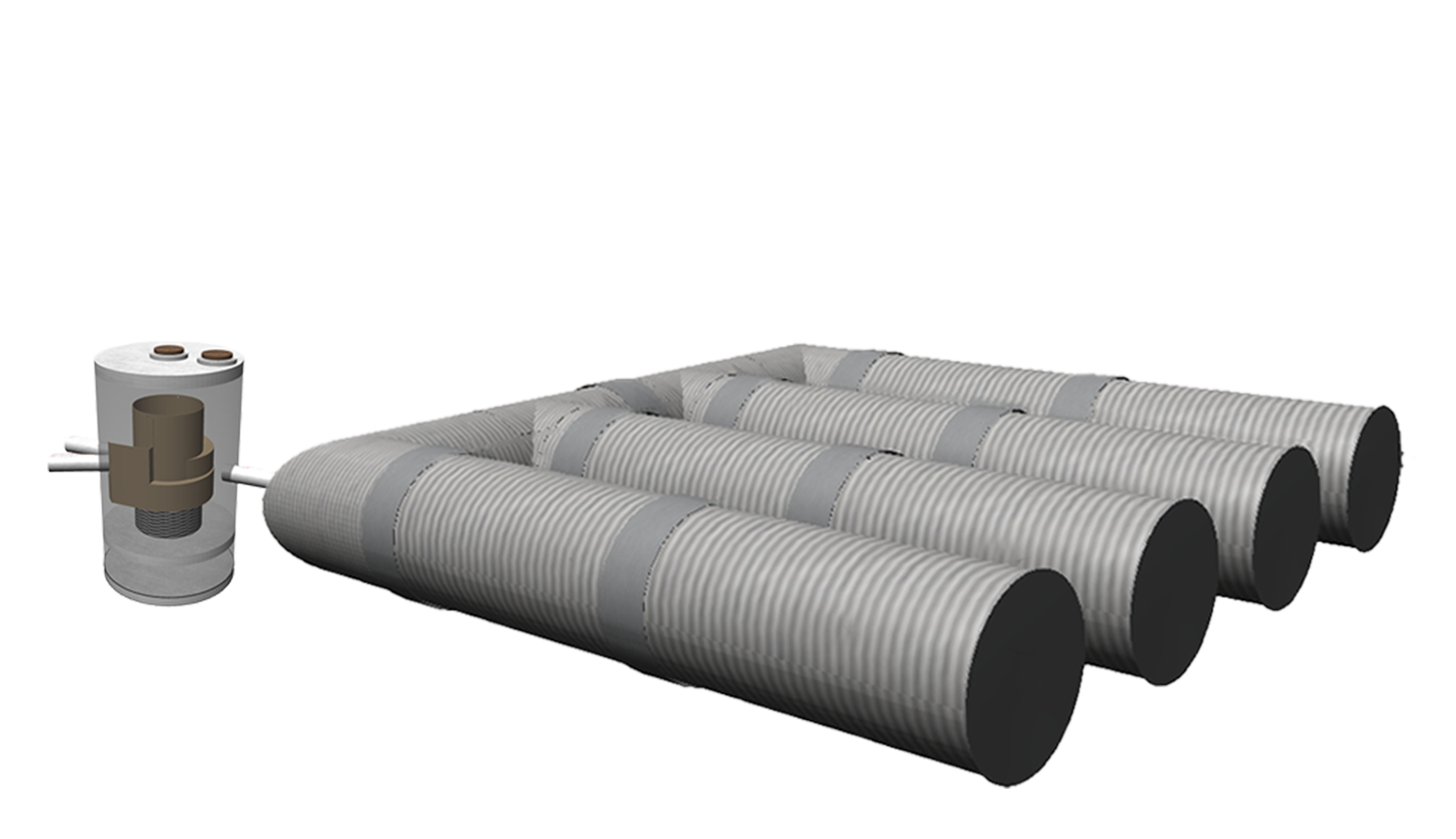

The Contech Design Center enables engineers to accelerate the design process for bridge and stormwater projects, generating project-specific drawings, engineering calculations, and CAD files while collaborating with Contech engineers. This helps reduce design time, ensures regulatory compliance, and improves constructability. |

|---|