Stay Connected

As a Gen-Xer, I am old enough to remember a time without cellphones, when getting connected with someone on the telephone literally meant being confined to a corded phone. Sometimes this was not very enjoyable - like trying to have a conversation with your crush on the kitchen wall phone (it had the longest cord) without mom trying to listen in or travelling in an unfamiliar area desperately searching for a working payphone. Thankfully, things have improved, and landlines have been replaced with amazing wireless technology. That said, over the years things have also progressed in the world of storm and wastewater pipe – now larger diameter conveyance systems can also benefit from updated technology to have a better connection. However, once this connection is made, it should last longer than a conversation with your sweetheart.

For a long-term pipe connection to be made, it must utilize a joint that will remain tight for the life of the system. There are several benefits to making a superior joint connection:

- Reduces pipe system overflows due to infiltration during rain events.

- Helps to prevent loss of soil around the pipe leading to surface sinkholes.

- Mitigates harmful discharges from polluting aquifers and the environment.

- Extends the overall service life of our pipeline infrastructure.

Also, poor joint performance can be expensive; dealing with I&I (inflow and infiltration) in wastewater systems can cost states, counties and municipalities millions of dollars annually. The excess flow caused by joint infiltration inundates the system and creates added costs for pumping, treatment, and overflow clean up. Severe I&I may even be fined by Federal regulators (EPA) resulting in additional financial consequences for taxpayers!

I&I can be caused by several factors such as cracks in the pipe wall, compromised structure connections, incorrect tie-ins, and seepage into manholes. However, one of the primary areas of infiltration (and exfiltration) in storm sewers and wastewater systems is from poor connections at the joints. Over the years, pipe systems can experience differential settlement, fluctuating groundwater and other factors leading to a loss of joint integrity through separation, misalignment, and damage. For conveyance systems, the pipe joints can be considered as “red flag” areas where future issues may occur.

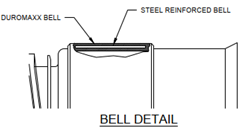

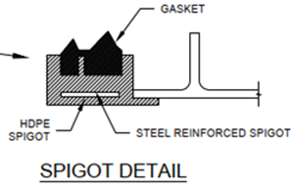

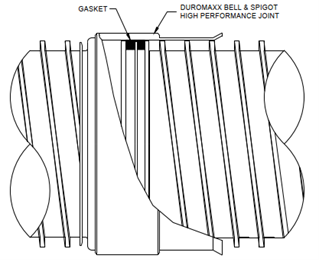

An example of a modern technology that is available today is the high-performance steel reinforced joint available with DuroMaxx® SRPE pipe. This joint was introduced in 2007 and utilizes an HDB (hydrostatic design basis) rated PE resin which is reinforced with steel to achieve watertight joints in 30” to 72” diameters and easily exceeds the requirements of ASTM D3212. The detail below illustrates how the steel reinforcement is fully encapsulated inside the plastic of both the bell and the spigot ends – this design prevents future movement, or “creep”, of the plastic over time. Once the joint is homed, the two layers of steel work together to compress, or “sandwich” the gasket and maintain joint integrity for the life of the pipe system.

Specifying a joint technology that will provide a better connection is one way to fight against future issues, but it is also a useful design practice to minimize the number of joints in a conveyance system to begin with. As an example, consider a 72-inch diameter pipe system that is 2,000 linear feet – utilizing typical 8-foot-long concrete pipe sections would result in a system comprised of 250 joints, whereas the more advanced DuroMaxx® pipe supplied in standard 14’ or 24’ sections would result in only 142 or 83 joints respectively.