- Pipe

- Bridges & Structures

- Walls

- Stormwater Management

- Erosion Control

- Start a Project

- Knowledge Center

- Technical Documents

Our local contacts are experts who are ready to help!

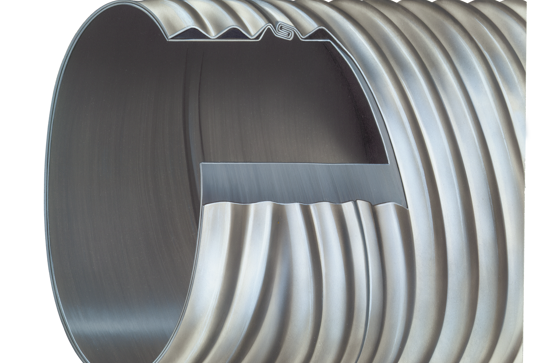

Smooth Cor™ consists of a standard corrugated steel pipe as its structural exterior shell and includes a hydraulically smooth steel liner. Both the interior liner and exterior shell are coated on both sides with a polymer coating. This combination makes Smooth Cor Pipe the economical and performance alternative to concrete in difficult situations such as weak soils, poor subsurface drainage conditions, steep slopes, and high fills.

Smooth Cor can be fabricated into any type of structure including tees, elbows, laterals, catch basins, manifolds and reducers. Pre-fabricated fittings are more economical and have superior hydraulic characteristics when compared to concrete structures.

Smooth Cor should be specified as an alternative under normal site conditions and specified exclusively under very difficult situations that demand the strength of CMP with positive joints and a hydraulically efficient smooth liner.

| FEATURES | BENEFITS |

|---|---|

|

Smooth steel liner |

Manning’s “n” of 0.012, outperforms reinforced concrete pipe |

|

Corrugated steel shell |

Provides structural strength to outperform rigid pipe |

|

Polymer coating |

Protects against abrasion and corrosion to provide a service life of 100 + years |

|

High beam strength |

Superior to concrete pipe in many difficult situations such as weak soils, poor subsurface drainage conditions, steep slopes and high fills |

|

Lightweight |

Easier and less expensive to install than concrete pipe |

The rugged, corrugated steel shell of Smooth Cor pipe supplies the structural strength to outperform rigid pipe, while a smooth interior steel liner provides a Manning’s “n” of 0.012. This combination makes Smooth Cor pipe both the economical and performance alternate to concrete in many difficult situations such as weak soils, poor subsurface drainage conditions, steep slopes, and high fills.

Technical Documents

Case Studies

Explore the case studies libraryProject Design Worksheets

POPULAR DOWNLOADS

Our team is ready to provide you with expert advice and assistance on local regulatory requirements, resulting in faster approvals.

Our engineers can review your requirements, weigh all options, and recommend the optimal solution to integrate with your site designs.

Our engineers can assist by providing product specific engineering calculations such as hydraulics, buoyancy, foundation reactions, and unit sizing.

We can quickly provide engineer’s cost

estimates to assist with your solution

selection process.

Our engineers can provide site-specific drawings for proposals, project meetings, and submittals, helping you be more efficient with your time.

Contractors know time is money, so we provide preconstruction meetings, delivery coordination, and on-site installation support to ensure a timely, smooth installation.