- Pipe

- Bridges & Structures

- Walls

- Stormwater Management

- Erosion Control

- Start a Project

- Knowledge Center

- Technical Documents

The world of sanitary and storm sewers has seen a growing need for larger diameters to carry water. As pipe sizes increase, designing manway access becomes more challenging as larger pipes necessitate larger manholes or concrete boxes. It's not uncommon to resort to cast-in-place structures as the primary solution, which can be both time-consuming and expensive. However, with ongoing technological advancements and the increased use of thermoplastic pipe materials, alternative manhole solutions have been steadily gaining popularity. Many designers and regulators are recognizing the benefits of exploring alternatives to the traditional standard concrete manhole or box structures.

Fall is finally here! The sun rises a little later and sets a little sooner, the days and nights become cooler. This causes the leaves to change color, and we get to see the brilliance of nature. This is my favorite time of the year for several reasons but most especially it means it’s Football season. The gridiron of gladiators is truly the best sport on the planet. September, October and November tailgates at the stadium are awesome that is, of course, if it isn’t raining.

As a Gen-Xer, I am old enough to remember a time without cellphones, when getting connected with someone on the telephone literally meant being confined to a corded phone. Sometimes this was not very enjoyable - like trying to have a conversation with your crush on the kitchen wall phone (it had the longest cord) without mom trying to listen in or travelling in an unfamiliar area desperately searching for a working payphone.

When a culvert or storm sewer reaches the end of its useful service life, the option to excavate and replace is commonplace. However, having the additional option to reline the existing structure to provide a structural solution can save significant time and money. A key to determining whether or not to excavate and replace or to structural reline an existing pipe is to assess the condition of the current pipe.

In the realm of construction products, an ongoing discussion among engineers, contractors, and project partners often centers around the strength of different materials. Traditionally, strength has been associated with products that remain rigid and unyielding under load, such as reinforced concrete walls or heavy steel beams.

We recently held a Pipe webinar on Irrigation Canals entitled, "Irrigation Solutions | Sustainable Management of Our National Resources," and we wanted to include just a few key points here on the Pipe Blog that may be of particular interest to those of you who missed it. Irrigation districts are increasingly deciding to pipe existing open channels to save water, reduce maintenance, and improve public safety. There are a few ways that this can be accomplished, from reinforced concrete pipe (RCP) and large-diameter fiberglass pipe to steel reinforced polyethylene (SRPE).

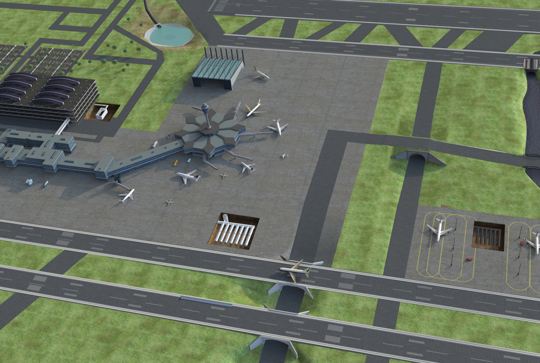

DuroMaxx® steel reinforced polyethylene tanks are an efficient and innovative option for Airport Authorities looking to improve the way in which spent deicing fluid and aqueous film forming foam (AFFF) is contained. This product merges the advantages of steel with the advantages of HDB-rated polyethylene resin to create a 100 year+ service life, good hydraulics, and watertight joints.

I was excited to be able to conduct a little research into the history and development of the Chicago Caisson Method in preparation for the recently held Vertical CSP Foundations webinar. I learned quite a bit and wanted to share some of the key takeaways with all of you

Deep foundations along with Gravity spread support the largest wind turbine generators (4.5 MW turbines currently) in operation. As the turbines are increasing in size, Gravity spreads are approaching the limits of both their capacity and economical limits. Deep foundations are positioned very well for these larger applications due to their design advantages.

SUBSCRIBE

The Pipe Blog is featured on the Contech Site Solutions Newsletter. Get insights, news, tip & tricks delivered directly to your inbox. Sign Up Today to Receive.