In the smash hit 1987 film, The Princess Bride, Princess Buttercup violently pushes her beloved Westley down an endlessly sloped hillside. We know what you’re thinking: “Could a corrugated metal pipe possibly be placed underneath such a sloped hill? Inconceivable!” This question has plagued men and women alike since the invention of corrugated steel pipe. Thankfully, AASHTO and ASTM have spelled out a solution for us all. And that solution, my friends, is graphically depicted below, which will be elaborated on…

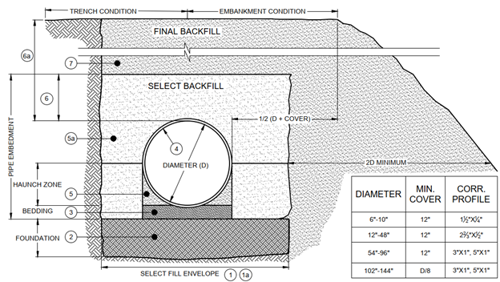

Let’s start with the basics. The circle shown above is a representation of a corrugated metal pipe. The corrugated pipe needs to be supported adequately by a well compacted select backfill. The amount of select backfill needs to be a MINIMUM of 2’-0” beyond the springline of the pipe. Now that we've got the basics covered, we are about to enter into intermediate territory. The horizontal distance from the select backfill zone to the sloped embankment is a MINIMUM of two times the pipe diameter. Now that we’re advanced, let’s do an example!

Say we have a 120” diameter corrugated metal pipe buried underneath the hill that Princess Buttercup and Westley tumbled down. We have compacted the select backfill around the corrugated metal pipe. We now calculate the minimum distance between the select backfill zone and the sloped embankment: two times the pipe diameter size. We need a minimum distance of 20’ from the select backfill to the sloped embankment for a 120” diameter pipe.

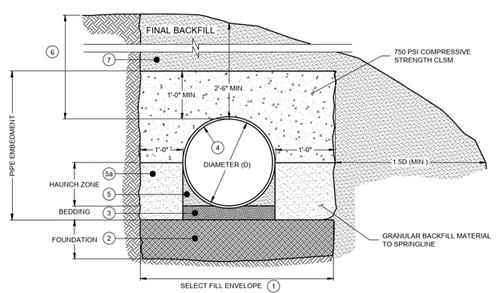

We know what you’re thinking: you can’t follow ASTM or AASHTO because you have even LESS than 20’ to work with. We have you covered…in concrete. If you were to use a cementitious backfill above the springline of the corrugated metal pipe, you will be able to reduce the distance between the select backfill zone and the side of the embankment.

If we were to use 750psi compressive strength concrete above the springline of the pipe, we can reduce the distance from the select backfill zone to the sloped embankment to a minimum distance of 1.5 times the pipe diameter. So, for a 120” diameter corrugated metal pipe, the distance from the select backfill zone to the sloped embankment would only need to be 15’. Now that’s conceivable!

If you want to reduce that spacing even more, consider higher strength concrete options. Or just give your local Contech representative a call, and we’ll be able to walk you through your options.