- Pipe

- Bridges & Structures

- Walls

- Stormwater Management

- Erosion Control

- Start a Project

- Knowledge Center

- Technical Documents

Our local contacts are experts who are ready to help

As stormwater quality regulations become more stringent, engineers need a filtration device that can tackle the most challenging pollutants and provide the flexibility to meet the needs of a variety of sites.

The Stormwater Management StormFilter® is an underground stormwater treatment device comprised of one or more structures that house rechargeable, media-filled cartridges that trap particulates and adsorb pollutants from stormwater runoff such as total suspended solids, hydrocarbons, nutrients, metals, and other common pollutants. With media options to target multiple or specific pollutants, multiple system configurations, and field and laboratory performance verified by the most stringent stormwater technology evaluation organizations; the StormFilter provides engineers the most flexible and most reliable manufactured treatment technology available.

| Feature | Benefit |

|---|---|

| Siphon actuated, high surface area media cartridges | Stormwater is drawn evenly through the filter media providing efficient, effective stormwater treatment |

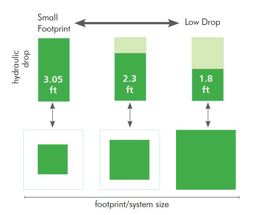

| Multiple cartridge heights | Flexibility to meet site-specific hydraulic needs and reduce system size and costs |

| Multiple media options | Ability to target specific pollutants of concern including TSS, phosphorus, heavy metals, and hydrocarbons |

| Internal peak bypass and multiple configurations | Design flexibility to meet your unique site requirements |

| Maintenance intervals of one to five years | Fewer maintenance events and reduced long-term ownership costs |

| Performance verified by both the WA DOE and NJ DEP | Superior pollutant capture with confidence |

| Arrives to the jobsite fully assembled | Factory build ensures quality and a simple, fast installation onsite |

Flexibility to reduce size and costs...

Every site is different, and one size does not fit all. Multiple cartridge heights give you design flexibility to design the StormFilter specifically for your site and reduce the cost of the system for the owner.

Flexibility to accommodate flows, project footprints, and hydraulics ...

The structures that house the filter cartridges can be constructed in a variety of ways to accommodate a wide range of flows, project footprints, and variable hydraulic conditions. Standard configurations include catch basin, manhole, vault, curb inlet, and linear grate. Advanced configurations include:

Every manufactured filtration device will eventually need routine maintenance. The question is how often and how much it will cost. Proper evaluation of long-term maintenance costs should be a consideration when selecting a manufactured treatment device. The StormFilter has been optimized to reduce long-term maintenance costs with proven, repeatable performance in the laboratory and in the field.

Technical information for this product is located in the technical guide’s section.

Designing, manufacturing and installing high-volume stormwater detention and treatment systems requires expert engineering, planning, and logistical support to manage costs and keep the project on schedule and under budget. When you need a proven, large scale stormwater management system, “Go Big” with Contech.

The Stormwater Management StormFilter, Jellyfish Filter, and the Kraken Filter provide the highest level of treatment and meet the most stringent regulatory requirements. These low maintenance systems combine pretreatment and filtration, and are able to target site-specific pollutants to meet your water quality goals. Our field-proven products have earned hundreds of standalone BMP approvals from regulatory agencies nationwide.

The Stormwater Management StormFilter, Jellyfish Filter, and the High Capacity Kraken Filter can be easily configured as decentralized pretreatment systems for Low Impact Development Designs.

Media filtration systems - like our StormFilter, Jellyfish Filter, and Kraken Filter are able to remove the most challenging pollutants from stormwater, including total phosphorus, soluble metals, oil, and very fine particles. Available in a variety of configurations (vault, manhole, catch basin, high flow and volume), these systems can be engineered to treat a wide range of flows within your drainage system and capture pollutants prior to discharge off-site.

Specifications Standard Details

Case Studies

Explore the case studies libraryProject Design Worksheets

Our team is ready to provide you with expert advice and assistance on local regulatory requirements, resulting in faster approvals.

Our engineers can review your requirements, weigh all options, and recommend the optimal solution to integrate with your site designs.

Our engineers can assist by providing product specific engineering calculations such as hydraulics, buoyancy, foundation reactions, and unit sizing.

We can quickly provide engineer’s cost

estimates to assist with your solution

selection process.

Our engineers can provide site-specific drawings for proposals, project meetings, and submittals, helping you be more efficient with your time.

Contractors know time is money, so we provide preconstruction meetings, delivery coordination, and on-site installation support to ensure a timely, smooth installation.